The Impact of 3D Printing on Rapid Weapon Prototyping

In recent years, the defense industry has witnessed a transformational shift due to the advent of 3D printing technology. This innovative method of manufacturing is not just a passing trend; it is fundamentally changing how weapons are designed and produced. Imagine being able to create a complex weapon prototype in a matter of days rather than months. That’s the power of 3D printing! By allowing for rapid prototyping, this technology is reshaping military strategies and enhancing operational readiness. But what does this mean for the future of defense? Let’s dive deeper into how 3D printing is revolutionizing weapon prototyping and what implications this holds for the industry.

3D printing, also known as additive manufacturing, involves creating three-dimensional objects layer by layer from digital models. This process utilizes a variety of materials, including plastics, metals, and even ceramics, to produce intricate designs that were once impossible to achieve with traditional manufacturing techniques. The principle is simple: a digital blueprint is translated into a physical object, allowing for a high degree of customization and flexibility. The materials used can vary widely, from lightweight polymers to robust metal alloys, each serving different purposes depending on the intended application. As we explore the implications of 3D printing in weapon prototyping, it’s crucial to understand this foundational technology and its capabilities.

Traditionally, weapon prototyping has been a labor-intensive process, often requiring extensive resources and time. The historical methods involved machining, casting, and assembly, which not only took a long time but also incurred significant costs. As military needs evolved, so did the demand for faster and more efficient prototyping solutions. The limitations of conventional methods became glaringly apparent, leading to the exploration of alternative technologies. This evolution set the stage for the adoption of 3D printing in the defense sector, paving the way for innovations that could keep pace with the rapidly changing landscape of warfare.

The challenges faced in conventional weapon prototyping are numerous and complex. For starters, time efficiency is a critical factor. Traditional methods often lead to lengthy development cycles, which can hinder timely responses to emerging threats. Imagine a scenario where a new weapon system is needed urgently; if it takes months to prototype, the military could be at a disadvantage.

Additionally, the cost implications of traditional prototyping are substantial. The financial burdens include material waste, labor costs, and the overhead associated with maintaining extensive facilities. In contrast, 3D printing significantly reduces these costs by minimizing waste and streamlining the production process. This not only saves money but also allows for more resources to be allocated to other critical areas of defense.

The advantages of utilizing 3D printing for weapon prototypes are compelling. One of the most notable benefits is the enhanced design flexibility it offers. Designers can experiment with complex geometries and intricate features that would be impractical or impossible to achieve with traditional methods. This leads to improved performance and functionality in weapon systems. Moreover, 3D printing drastically reduces production times, allowing for rapid iterations and modifications based on testing and feedback. The ability to customize designs quickly means that military personnel can receive tailored solutions that meet their specific operational needs.

Real-world applications of 3D printing in the military are already showcasing its effectiveness. For instance, several armed forces have successfully implemented 3D printed components in their weapon systems, demonstrating not only the technology’s viability but also its potential for future advancements.

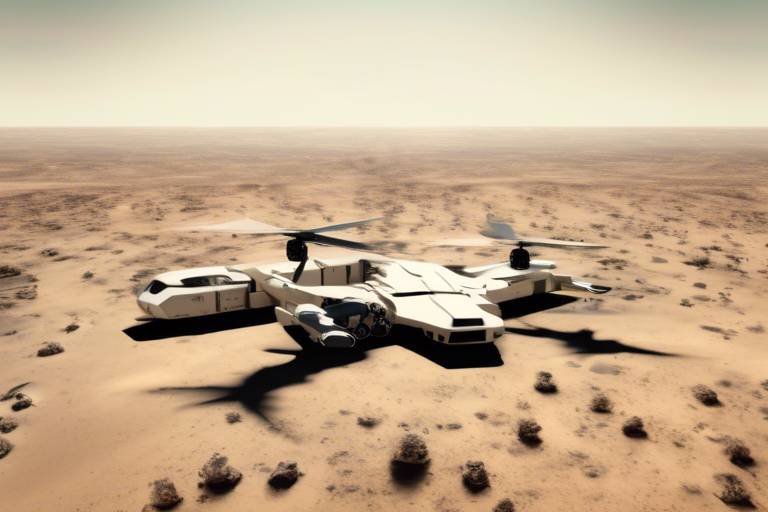

One notable example is the development of 3D printed drones, which have been designed with unique features that enhance their stealth and maneuverability. These designs would have been challenging to achieve with traditional manufacturing methods due to the complexity involved. The ability to produce such innovative designs rapidly is a game changer for military operations.

Field tests of 3D printed weapons have yielded promising results, with military personnel reporting high levels of satisfaction regarding the performance of these prototypes. Metrics such as accuracy, durability, and functionality have shown that 3D printed weapons can compete with, and in some cases exceed, their traditionally manufactured counterparts.

As we look ahead, the future of weapon prototyping is poised for even more significant changes. The integration of artificial intelligence (AI) and automation into the 3D printing process is expected to enhance efficiency and effectiveness further. Imagine a scenario where AI algorithms optimize designs in real-time based on battlefield data, leading to even faster and more effective weapon systems.

The potential for AI to revolutionize weapon development cannot be overstated. By analyzing vast amounts of data, AI can provide insights that inform design choices, ultimately leading to superior weapon systems that are tailored to meet the specific needs of military operations.

However, with great power comes great responsibility. The implications of 3D printing in weaponry raise significant regulatory and ethical concerns. Manufacturers and governments must navigate the complexities of creating policies that ensure the responsible use of this technology. Questions surrounding the potential for misuse and the ethical ramifications of producing weapons in a decentralized manner are critical to address as we move forward.

- What is 3D printing? 3D printing, or additive manufacturing, is a process that creates three-dimensional objects by layering materials based on digital designs.

- How does 3D printing improve weapon prototyping? It allows for rapid production, reduces costs, and offers greater design flexibility compared to traditional methods.

- Are there any risks associated with 3D printed weapons? Yes, there are regulatory and ethical concerns regarding the potential misuse of 3D printed weapons and the need for responsible manufacturing practices.

Overview of 3D Printing Technology

3D printing, also known as additive manufacturing, is a transformative technology that has taken the world by storm. It involves creating three-dimensional objects layer by layer from a digital model. The process begins with a computer-aided design (CAD) file, which is sliced into thin horizontal layers. This digital blueprint is then sent to a 3D printer, which uses various materials to build the object from the ground up. The beauty of 3D printing lies in its versatility; it can utilize a range of materials including plastics, metals, ceramics, and even biological substances.

The core principle of 3D printing is simple yet revolutionary: instead of subtracting material to create a shape, as in traditional manufacturing methods, 3D printing adds material. This approach allows for the creation of complex geometries that would be impossible or prohibitively expensive to produce with conventional techniques. For instance, intricate lattice structures or customized components tailored to specific needs can be realized effortlessly, giving designers and engineers unprecedented freedom.

There are several popular 3D printing technologies, each with its unique processes and applications. Some of the most common methods include:

- Fused Deposition Modeling (FDM): This method extrudes thermoplastic filaments through a heated nozzle, building objects layer by layer.

- Stereolithography (SLA): In this technique, a laser cures liquid resin into solid plastic, allowing for high-resolution prints.

- Selective Laser Sintering (SLS): This process uses a laser to fuse powdered material, creating durable and functional parts.

As 3D printing technology evolves, so do the materials used. Innovations in material science have led to the development of advanced composites and even bio-printed tissues, expanding the potential applications of 3D printing beyond just prototyping. In the defense sector, for example, the ability to produce lightweight yet strong components can significantly enhance the performance of weapon systems.

Furthermore, the impact of 3D printing on supply chains cannot be overstated. Traditional manufacturing often relies on lengthy supply chains, which can be vulnerable to disruptions. With 3D printing, parts can be produced on-demand, reducing the need for extensive inventories and minimizing lead times. This capability is crucial in defense scenarios where rapid response is essential.

In summary, 3D printing technology is not just a passing trend; it is a game-changer that is reshaping industries, particularly in weapon prototyping. Its ability to create complex designs, utilize diverse materials, and streamline production processes makes it an invaluable tool for modern military applications. As we delve deeper into its historical context and benefits, it becomes clear that 3D printing is not only enhancing existing capabilities but also paving the way for future innovations in weapon design and manufacturing.

- What materials are commonly used in 3D printing? 3D printing can use a variety of materials, including plastics, metals, ceramics, and even biological materials.

- How does 3D printing differ from traditional manufacturing? Unlike traditional methods that subtract material, 3D printing adds material layer by layer to create objects.

- What are the advantages of 3D printing in weapon prototyping? Advantages include faster production times, design flexibility, reduced costs, and the ability to create complex geometries.

- Can 3D printing be used for final production parts? Yes, many industries are now using 3D printing for final production parts, especially where customization and rapid prototyping are needed.

Historical Context of Weapon Prototyping

The journey of weapon prototyping has been a fascinating one, marked by a series of innovations and challenges that have shaped the way military technology evolves. In the early days, weapon design was primarily a manual process, heavily reliant on skilled artisans who crafted each component with precision. This labor-intensive method often led to lengthy development cycles, where the time from concept to deployment could stretch into years. Imagine a world where the speed of warfare was dictated not by the urgency of need but by the slow pace of production; this was the reality of traditional weapon prototyping.

As warfare technology advanced, so did the methods of weapon prototyping. The introduction of computer-aided design (CAD) in the late 20th century revolutionized the field, allowing designers to create intricate models and run simulations before any physical production began. This shift not only improved accuracy but also reduced the chances of catastrophic failures in the field. However, despite these advancements, traditional prototyping methods still faced significant challenges, particularly in terms of time and cost.

Traditional weapon prototyping methods were often plagued by several key challenges:

- Time Efficiency: The lengthy development cycles associated with conventional methods meant that military forces could not always respond swiftly to emerging threats. When a new weapon design was needed, the process could take months or even years to complete, leaving troops vulnerable.

- Cost Implications: The financial burden of traditional prototyping was substantial. High material waste and extensive labor costs made it difficult for defense contractors to stay within budget. In an era where military funding is often scrutinized, these inefficiencies raised red flags.

- Resource Availability: Access to specialized materials and skilled labor could also limit the ability to prototype new designs. In many cases, the materials required for advanced weapon systems were not readily available, leading to delays and increased costs.

These challenges highlighted an urgent need for innovative solutions, paving the way for the adoption of 3D printing technology in the defense sector. With its ability to create complex geometries and reduce the time from design to production, 3D printing emerged as a game-changer, offering a glimpse into a future where rapid prototyping could become the norm rather than the exception.

In summary, the historical context of weapon prototyping reveals a landscape that has evolved significantly over the years. From the artisanal craftsmanship of the past to the high-tech innovations of today, each step has been driven by the need for efficiency, cost-effectiveness, and adaptability in an ever-changing battlefield. As we continue to explore the implications of 3D printing in weapon prototyping, it’s essential to recognize the lessons learned from traditional methods. They serve as a reminder of the importance of innovation in meeting the demands of modern warfare.

- What is the primary advantage of 3D printing in weapon prototyping?

3D printing allows for faster production times, reduced costs, and greater design flexibility compared to traditional methods. - How has 3D printing changed the defense industry?

It has revolutionized the way weapons are designed and produced, enabling rapid prototyping that can keep pace with the evolving nature of warfare. - Are there any ethical concerns with 3D printing weapons?

Yes, the ability to produce weapons easily raises significant ethical and regulatory questions about control, responsibility, and the potential for misuse.

Challenges in Traditional Prototyping

When we think about traditional weapon prototyping, it's almost like stepping into a time machine that takes us back to a world where speed and efficiency were often sacrificed at the altar of meticulous craftsmanship. The reality is that conventional methods come with a host of challenges that can make the whole process feel like an uphill battle. One of the most glaring issues is the time constraints that plague the defense industry. Imagine a scenario where a new threat emerges, and the clock is ticking. Traditional prototyping can lead to lengthy development cycles, sometimes stretching into months or even years. This delay can hinder military readiness and responsiveness, which is critical in the fast-paced world of defense.

Moreover, there's the financial burden associated with traditional methods. The costs can skyrocket due to various factors, including material waste and labor expenses. For instance, when creating a prototype, manufacturers often have to order large quantities of materials, only to find that the initial design wasn't quite right, leading to waste. This not only drains financial resources but also limits the ability to experiment with innovative designs. To put it simply, traditional prototyping can be a bit like trying to fill a bucket with holes—no matter how much you pour in, it seems like you're getting nowhere.

Additionally, the resource availability can be a significant challenge. In many cases, specialized materials and skilled labor are required to create weapon prototypes, which can be hard to come by. This scarcity can lead to bottlenecks in the production process, further delaying the development of critical military assets. It's akin to trying to bake a cake without the right ingredients; no matter how skilled the baker is, the cake just won't rise without the necessary components.

In summary, the challenges faced in traditional weapon prototyping are multifaceted and complex. From time inefficiencies to soaring costs and resource limitations, these obstacles highlight the pressing need for innovative solutions. As the defense sector looks to the future, the transition to more agile methods, such as 3D printing, becomes not just beneficial but essential.

- What are the main challenges in traditional weapon prototyping? Traditional weapon prototyping faces challenges such as lengthy development cycles, high costs due to material waste, and difficulties in obtaining specialized resources.

- How does 3D printing address these challenges? 3D printing significantly reduces development time, minimizes material waste, and allows for greater design flexibility, making it a more efficient alternative.

- Can 3D printing be used for all types of weapons? While 3D printing can be used for many types of weapons, it is particularly effective for prototypes and designs that require rapid iteration and customization.

Time Efficiency

When it comes to weapon prototyping, time is of the essence. Traditional methods often involve lengthy development cycles that can stretch into months or even years. Imagine a scenario where military forces are faced with an unexpected threat. The last thing they need is to be bogged down by a slow prototyping process. This is where 3D printing truly shines, offering a solution that not only accelerates the design phase but also shortens the entire production timeline.

With 3D printing, the process of moving from concept to prototype can be streamlined significantly. Designers can create a digital model and, within hours, have a physical prototype in hand. This rapid turnaround enables teams to test and refine their designs in real-time, making adjustments based on immediate feedback. For example, while traditional methods might require multiple iterations involving machining or molding, 3D printing allows for rapid iterations. This means that if a flaw is detected in the initial prototype, adjustments can be made swiftly and a new version can be printed almost immediately.

Moreover, the ability to produce prototypes on-demand means that military units can quickly adapt to changing circumstances. In situations where new threats emerge, having the capability to design and produce a weapon prototype within days rather than months can be a game changer. This not only enhances operational readiness but also ensures that military personnel are equipped with the most relevant and effective tools available.

In a world where speed and adaptability are crucial, the efficiency of 3D printing in weapon prototyping cannot be overstated. It allows for an agile response to threats, enabling defense forces to stay ahead of the curve. As this technology continues to evolve, we can expect even greater advancements in how quickly and effectively weapon prototypes can be developed, ensuring that our military remains at the forefront of innovation.

To further illustrate the time efficiency of 3D printing, consider the following table that compares traditional prototyping methods to 3D printing in terms of time taken for different stages of development:

| Prototyping Stage | Traditional Methods (Days) | 3D Printing (Days) |

|---|---|---|

| Design Phase | 30-60 | 1-3 |

| Prototype Production | 15-30 | 1-5 |

| Testing and Feedback | 10-20 | 1-2 |

| Total Time | 55-110 | 3-10 |

As you can see, the difference in time efficiency between traditional methods and 3D printing is staggering. This not only highlights the advantages of adopting 3D printing technology in weapon prototyping but also emphasizes the need for the defense industry to embrace these innovations to remain effective in a rapidly changing world.

- How does 3D printing improve weapon design?

3D printing allows for rapid prototyping, enabling designers to create and test multiple iterations quickly, leading to better and more innovative designs.

- What are the cost benefits of using 3D printing for weapon prototyping?

3D printing reduces material waste and labor costs, making it a more economical choice compared to traditional methods.

- Can 3D printed weapons be tested in the field?

Yes, many military applications have successfully tested 3D printed weapons in real-world scenarios, demonstrating their effectiveness and reliability.

- What is the future of 3D printing in the defense sector?

The future looks promising, with potential advancements in materials and integration with AI and automation to enhance efficiency and effectiveness.

Cost Implications

When we dive into the financial landscape of weapon prototyping, it becomes clear that traditional methods can be a serious drain on resources. Conventional prototyping often involves extensive material waste, labor costs, and protracted timelines that can escalate expenses. Imagine pouring money into a project that takes months, if not years, to complete, only to find out that the prototype doesn't meet the required specifications. This is a common scenario in the defense sector, where the stakes are high, and the need for precision is paramount.

One of the most significant advantages of 3D printing is its ability to dramatically reduce these costs. With additive manufacturing, materials are used more efficiently, and the waste that typically accompanies traditional subtractive methods is minimized. For instance, instead of cutting away excess material from a block, 3D printing builds the object layer by layer, utilizing only the necessary amount of material. This not only saves money but also allows for more sustainable practices in an industry that often grapples with environmental concerns.

Furthermore, the labor costs associated with traditional prototyping can be staggering. Skilled labor is required at various stages of the prototyping process, from design to fabrication. In contrast, 3D printing often requires fewer personnel, as the technology automates many of these tasks. This shift not only cuts down on the labor force needed but also allows existing workers to focus on more critical aspects of development, such as design innovation and quality control.

To put this into perspective, consider the following table that outlines the cost differences between traditional and 3D printing methods:

| Cost Category | Traditional Prototyping | 3D Printing |

|---|---|---|

| Material Waste | High | Low |

| Labor Costs | High | Reduced |

| Production Time | Months | Days |

| Overall Cost | Significantly Higher | More Economical |

In essence, the cost implications of adopting 3D printing technology in weapon prototyping are profound. By minimizing material waste, reducing labor costs, and speeding up production times, defense manufacturers can not only save money but also allocate resources more effectively. This shift allows for a more agile response to emerging threats, enabling rapid development cycles that are crucial in today's fast-paced military environment. As we continue to explore the transformative power of 3D printing, it becomes increasingly evident that the financial benefits are just as compelling as the technological advancements.

- What is 3D printing? 3D printing, or additive manufacturing, is a process that creates three-dimensional objects by layering materials based on digital models.

- How does 3D printing reduce costs in weapon prototyping? It minimizes material waste, lowers labor costs, and accelerates production times, making it a more economical choice compared to traditional methods.

- What are the limitations of traditional weapon prototyping? Traditional methods often involve high material waste, long production times, and significant labor costs, which can hinder timely responses to military needs.

Benefits of 3D Printing in Prototyping

When it comes to weapon prototyping, 3D printing is nothing short of a game changer. Imagine being able to create complex designs that were once deemed impossible with traditional manufacturing methods. This revolutionary technology offers a plethora of benefits that can significantly enhance the prototyping process in the defense industry. First and foremost, design flexibility is at the forefront. With 3D printing, engineers and designers can experiment with intricate geometries and structures without the constraints of conventional manufacturing. This means they can innovate and iterate designs rapidly, leading to more effective and efficient weapon systems.

Another major advantage is the reduction in production times. Traditional prototyping often involves multiple stages of production, which can stretch over weeks or even months. 3D printing, on the other hand, can produce a prototype in a matter of days, if not hours. This speed is crucial in military applications where timely responses to emerging threats can mean the difference between success and failure. For instance, if a new threat arises, the ability to quickly prototype and test new weapon designs is invaluable.

Moreover, cost-effectiveness is a significant consideration. Traditional methods often lead to high material waste and labor costs due to the complexities involved in machining and assembly. In contrast, 3D printing utilizes additive manufacturing techniques, which means materials are only used where necessary—resulting in less waste. This efficiency not only reduces costs but also allows for more sustainable practices in weapon development.

Customization is yet another area where 3D printing shines. Military operations often require specialized equipment tailored to specific missions or environments. With 3D printing, it’s possible to create custom components that meet unique specifications quickly. This adaptability ensures that military personnel have access to the right tools when they need them, enhancing operational readiness.

In summary, the benefits of 3D printing in weapon prototyping are manifold. From enhanced design flexibility and reduced production times to cost savings and increased customization, this technology is reshaping the landscape of defense manufacturing. As we delve deeper into this topic, it becomes clear that the implications of these benefits extend far beyond mere convenience; they fundamentally alter how the military approaches weapon design and production.

- What is 3D printing? 3D printing, or additive manufacturing, is a process of creating three-dimensional objects from a digital file by adding material layer by layer.

- How does 3D printing improve weapon prototyping? It allows for faster production, greater design flexibility, reduced costs, and enhanced customization options.

- Are there any limitations to 3D printing in weapon development? While 3D printing offers many advantages, it may not be suitable for all materials or large-scale production needs.

- What materials are commonly used in 3D printing for weapon prototypes? Common materials include plastics, metals, and composites, each chosen based on the specific requirements of the prototype.

Case Studies of 3D Printed Weapons

As we delve into the realm of 3D printed weapons, it's essential to recognize the tangible shifts this technology has brought to the defense sector. The adoption of 3D printing has not merely been a trend; it has revolutionized the way military forces approach weapon prototyping and production. Let's explore some fascinating case studies that illustrate the effectiveness and potential of 3D printing in weapon development.

One of the most notable examples comes from the United States military, which has successfully employed 3D printing to create parts for various weapon systems. For instance, the U.S. Army has utilized 3D printing to produce components for drones, significantly reducing the time required for prototyping and production. By using advanced materials like titanium and polymer composites, they can manufacture lightweight yet robust parts that enhance the performance of aerial vehicles.

Another compelling case is the work done by the U.S. Navy with their initiative known as the Naval Postgraduate School. Here, researchers have developed a 3D printed prototype of a small arms weapon, which was subjected to rigorous field testing. The results were impressive; the weapon not only performed reliably but also allowed for rapid modifications based on real-time feedback from operators. This ability to iterate quickly is a game-changer in military readiness.

Moreover, the Defense Distributed project has gained attention for its controversial yet groundbreaking approach to 3D printing firearms. Their creation, known as the Liberator, is a fully functional handgun that can be printed using a standard 3D printer. This case raises important discussions about accessibility, regulation, and the future of weapon manufacturing.

In addition to these examples, various defense contractors are now exploring the use of 3D printing to create customized weapon systems tailored to specific missions. The flexibility offered by this technology means that military units can have weapons designed for unique operational needs, enhancing their strategic capabilities. For instance, a special forces unit might require a compact, lightweight firearm that can be easily concealed, which 3D printing can facilitate.

To better illustrate the impact of 3D printing in weapon prototyping, let's take a look at a table summarizing some key case studies:

| Organization | Weapon Type | Key Benefits |

|---|---|---|

| U.S. Army | Drones | Reduced production time, lightweight materials |

| U.S. Navy | Small Arms | Rapid modifications, reliable performance |

| Defense Distributed | Handgun (Liberator) | Accessibility, innovative design |

| Various Defense Contractors | Customized Weapons | Mission-specific designs, strategic enhancement |

These case studies not only highlight the practical applications of 3D printing in weapon prototyping but also spark discussions about the future of military technology. The implications of such advancements are profound, as they suggest a shift towards a more agile and responsive defense strategy. As we continue to witness the integration of 3D printing into weapon development, the military landscape will inevitably transform, paving the way for enhanced capabilities and operational effectiveness.

Q: How does 3D printing improve weapon prototyping?

A: 3D printing allows for faster production times, reduced costs, and greater design flexibility, enabling rapid iterations and customization of weapon systems.

Q: What are some materials used in 3D printed weapons?

A: Common materials include polymers, metals like titanium, and composite materials, which provide the necessary strength and durability for military applications.

Q: Are there any ethical concerns regarding 3D printed weapons?

A: Yes, the ability to easily produce weapons raises significant ethical and regulatory questions, particularly concerning accessibility and the potential for misuse.

Q: What is the future of 3D printing in the defense industry?

A: The future looks promising, with advancements in materials and techniques expected to further enhance the capabilities of 3D printing in weapon development, potentially integrating AI and automation.

Innovative Designs

When we think about 3D printing, the first image that often comes to mind is a simple plastic toy or a basic prototype. However, the reality is far more exciting, especially in the realm of weapon prototyping. The advent of 3D printing has ushered in a new era of that push the boundaries of what is possible in weaponry. Imagine a world where military engineers can create complex weapon systems with intricate geometries that were previously deemed impractical or impossible using traditional manufacturing methods.

One of the most remarkable aspects of 3D printing is its ability to facilitate the creation of lightweight yet durable components. For instance, the U.S. military has begun experimenting with 3D-printed drone parts that not only reduce weight but also enhance performance. By utilizing advanced materials such as titanium alloys and carbon fiber composites, these designs can withstand extreme conditions while being significantly lighter than their traditionally manufactured counterparts. This is crucial in military operations where every ounce counts.

Moreover, the flexibility of 3D printing allows for rapid iterations of designs. Engineers can quickly modify and test new ideas without the lengthy process of tooling and setup that traditional methods require. For example, a recent project involved the rapid prototyping of a new type of grenade launcher. By using 3D printing, designers were able to experiment with various shapes and sizes, ultimately leading to a more ergonomic and effective weapon. The ability to tweak designs on-the-fly not only saves time but also fosters a culture of innovation.

Another exciting development is the potential for customization. Imagine a soldier being able to personalize their weapon to suit their specific needs, whether it's adjusting the grip size, adding attachments, or changing the color scheme. 3D printing enables this level of customization, allowing for a more tailored approach to weapon design. This personalization can enhance usability and improve the overall effectiveness of the weapon in the field.

To illustrate the impact of these innovative designs, let’s take a look at a few notable examples:

| Weapon Type | 3D Printing Application | Benefits |

|---|---|---|

| Drone Components | Lightweight frames and parts | Enhanced maneuverability and reduced weight |

| Grenade Launcher | Rapid prototyping of ergonomic designs | Improved user comfort and effectiveness |

| Custom Firearms | Personalized grips and attachments | Better fit and functionality for individual users |

As we continue to explore the possibilities of 3D printing in weapon design, it's clear that this technology is not just a passing trend; it's a game-changer. The ability to create innovative designs that are lighter, more efficient, and customizable is revolutionizing how we think about military hardware. The implications extend beyond just the battlefield, influencing the entire defense industry as it adapts to the rapid pace of technological advancement.

In conclusion, the integration of 3D printing into weapon prototyping is paving the way for a future where creativity and functionality go hand in hand. As designers and engineers push the envelope of what’s possible, we can expect to see even more groundbreaking innovations that redefine our understanding of modern warfare.

- What materials are commonly used in 3D printing for weapons?

Materials like titanium, carbon fiber, and specialized polymers are frequently used due to their strength and lightweight properties.

- How does 3D printing improve the speed of weapon prototyping?

3D printing allows for rapid iterations and modifications of designs without the need for extensive tooling, significantly reducing development time.

- Can 3D printing be used for mass production of weapons?

While 3D printing is primarily used for prototyping, advancements are being made towards using it for low-volume production runs, especially for specialized or custom designs.

Field Testing Results

Field testing of 3D printed weapons has emerged as a crucial phase in validating the effectiveness and reliability of these innovative prototypes. The results from various military exercises have been nothing short of groundbreaking. For instance, during a recent operation, a series of 3D printed drones were deployed, showcasing their operational capabilities in real-time scenarios. The feedback from military personnel involved in the tests highlighted several key aspects:

- Performance: The 3D printed weapons demonstrated impressive accuracy and reliability, matching or even exceeding the performance of traditionally manufactured counterparts.

- Durability: Initial concerns regarding the structural integrity of 3D printed materials were alleviated as these prototypes withstood rigorous testing conditions.

- Operational Flexibility: The ability to quickly adapt designs based on immediate battlefield needs proved invaluable, allowing for rapid modifications that were not feasible with conventional manufacturing.

Moreover, a comparative analysis of performance metrics revealed that 3D printed prototypes not only reduced assembly time but also minimized logistical challenges. The table below summarizes the key performance indicators observed during the field tests:

| Prototype Type | Accuracy (%) | Durability (hours under stress) | Modification Time (hours) |

|---|---|---|---|

| 3D Printed Drone | 95 | 48 | 2 |

| Traditional Drone | 90 | 36 | 12 |

This data illustrates that not only do 3D printed weapons hold their own against traditional designs, but they also offer significant advantages in terms of adaptability and responsiveness. The military's growing enthusiasm for 3D printing technology is evident, as it empowers them to meet modern warfare's dynamic demands. As these prototypes continue to undergo rigorous testing, the implications for future military strategies are profound, paving the way for a new era of weapon development.

Q1: What are the main advantages of using 3D printing for weapon prototyping?

A1: The main advantages include enhanced design flexibility, reduced production times, improved customization options, and lower costs compared to traditional manufacturing methods.

Q2: How does the durability of 3D printed weapons compare to traditional ones?

A2: Recent field tests indicate that 3D printed weapons can match or exceed the durability of traditional weapons, withstanding rigorous conditions effectively.

Q3: Are there any regulatory concerns associated with 3D printed weapons?

A3: Yes, the rise of 3D printed weapons raises significant regulatory and ethical considerations that need to be addressed to ensure responsible development and use.

Future Trends in Weapon Prototyping

The landscape of weapon prototyping is on the brink of a significant transformation, largely driven by the rapid advancements in 3D printing technology. As we look to the future, it becomes clear that this innovative approach will not only redefine how weapons are designed and produced but will also shape the strategies employed by military forces around the globe. Imagine a world where the time from concept to battlefield-ready weapon is reduced to mere days or even hours! This is not just a dream; it's becoming a reality.

One of the most exciting trends is the integration of artificial intelligence (AI) and automation into the 3D printing process. AI can analyze vast amounts of data to optimize designs, predict potential failures, and even suggest improvements based on battlefield conditions. For instance, imagine a scenario where AI algorithms can rapidly assess the performance of various prototypes under simulated combat conditions, allowing engineers to tweak designs in real-time. This synergy between AI and 3D printing could lead to a new era of smart weapons that adapt to their environment, enhancing operational effectiveness.

Moreover, the materials used in 3D printing are evolving at an astonishing pace. Traditional plastics are being replaced with advanced composites and even metals that offer superior strength and durability. These new materials not only enhance the performance of the prototypes but also open doors to designs that were previously thought impossible. For example, researchers are experimenting with self-healing materials that could repair themselves during combat, drastically improving the longevity and reliability of weapon systems.

Another trend to watch is the move towards decentralized manufacturing. With 3D printing technology becoming more accessible, military units could potentially produce their own weapons on-site, tailored to their specific needs. This would not only reduce the reliance on supply chains but also allow for rapid modifications based on immediate tactical requirements. Imagine a unit in the field being able to print a replacement part for a weapon system or even a completely new weapon within hours of identifying a need!

However, as we embrace these advancements, we must also navigate the regulatory and ethical considerations that come with them. The proliferation of 3D printing technology raises questions about accountability, especially if a weapon malfunctions or is used inappropriately. Governments and manufacturers will need to establish clear guidelines to ensure that these powerful tools are used responsibly. This includes considering who has access to 3D printing capabilities and how those capabilities are monitored.

In conclusion, the future of weapon prototyping is bright, filled with possibilities that could revolutionize military operations. As 3D printing continues to evolve, we can expect faster, more efficient, and highly customized weapon systems that not only meet the demands of modern warfare but also adapt to them. The combination of AI, advanced materials, and decentralized manufacturing will undoubtedly change the face of defense technology, making it an exciting time for both innovators and military strategists alike.

- How does 3D printing improve weapon prototyping?

3D printing allows for faster production times, greater design flexibility, and reduced costs compared to traditional manufacturing methods.

- What materials are used in 3D printed weapons?

Advanced composites, metals, and even self-healing materials are being explored to enhance the performance and durability of 3D printed weapons.

- Can AI influence weapon design?

Yes, AI can analyze data to optimize designs, predict failures, and suggest real-time improvements, making weapon systems smarter and more effective.

- What are the ethical implications of 3D printed weapons?

The rise of 3D printing in weaponry raises concerns about accountability, access, and responsible use, necessitating clear regulations and guidelines.

Integration with AI and Automation

As we look towards the horizon of weapon prototyping, the integration of artificial intelligence (AI) and automation stands out as a game-changer. Imagine a world where machines not only create but also learn from their creations. This is not just a sci-fi fantasy; it’s becoming a reality in the defense sector. The synergy between 3D printing and AI can drastically enhance the speed and efficiency of weapon development, making it possible to respond to threats in real time.

AI can analyze vast amounts of data to identify the most effective designs and materials for weapon prototypes. By utilizing machine learning algorithms, AI can predict which designs will perform best under various conditions, thus reducing the trial-and-error phase traditionally associated with prototyping. This predictive capability not only speeds up the design process but also ensures that the prototypes produced are optimized for performance.

Furthermore, automation can streamline the production process, allowing for the rapid scaling of successful designs. For instance, once a prototype has been validated, automated systems can take over to produce multiple units quickly and efficiently. This means that military forces can have access to advanced weaponry faster than ever before, ensuring they are always one step ahead of potential adversaries.

However, the integration of AI and automation is not without its challenges. There are significant regulatory and ethical considerations that must be addressed. Questions arise about accountability: if an AI system makes a decision that leads to unintended consequences, who is responsible? Moreover, there is the concern of ensuring that automated systems operate within the bounds of international law and ethical standards. As we delve deeper into this new frontier, it is crucial for manufacturers and governments to establish guidelines that govern the use of AI in weapon development.

In conclusion, the integration of AI and automation with 3D printing technology promises to revolutionize the landscape of weapon prototyping. By harnessing these advancements, the defense industry can achieve unprecedented levels of efficiency and effectiveness. However, as we embrace these innovations, we must also tread carefully, ensuring that we uphold ethical standards and regulatory frameworks to guide this powerful technology.

- What is the role of AI in 3D printing for weapon prototyping? AI helps optimize designs and predict performance, making the prototyping process faster and more efficient.

- How does automation improve the production of weapon prototypes? Automation allows for rapid scaling and consistent quality in production, significantly reducing the time required to manufacture multiple units.

- What ethical concerns arise from integrating AI in weapon development? There are concerns about accountability, decision-making processes, and ensuring compliance with international laws.

- Can AI completely replace human involvement in weapon prototyping? While AI can enhance efficiency, human oversight is crucial to ensure ethical standards and accountability are maintained.

Regulatory and Ethical Considerations

The advent of 3D printing technology in weapon prototyping has sparked a heated debate surrounding . As this innovative technology continues to evolve, it raises critical questions about its implications for national security, public safety, and the moral responsibilities of manufacturers and governments. How do we ensure that these powerful tools are used responsibly? What frameworks need to be established to govern their use?

One of the primary concerns revolves around the potential for misuse. With the ability to create weapons in a matter of hours, the risk of falling into the wrong hands increases significantly. Imagine a world where anyone with access to a 3D printer could produce a firearm or explosive device. This prospect is not just a distant nightmare; it's a reality that regulators must address. Countries around the world are grappling with how to legislate the production of 3D printed weapons, often struggling to keep pace with the rapid technological advancements.

Moreover, the ethical implications of 3D printing in weaponry extend beyond just regulation. Manufacturers face a moral dilemma: should they produce designs that could potentially harm others? The line between innovation and responsibility becomes blurred when profits are involved. Companies must consider their role in society and the potential consequences of their creations. The question arises: can we balance the benefits of rapid prototyping with the inherent risks it poses?

In light of these challenges, several regulatory frameworks are being proposed to mitigate risks associated with 3D printed weapons. These include:

- Licensing Requirements: Mandating licenses for individuals and organizations that wish to produce firearms using 3D printing technology.

- Material Control: Implementing restrictions on the types of materials that can be used in 3D printing to prevent the creation of dangerous weapons.

- Design Registration: Requiring manufacturers to register their designs with a governing body to monitor and control the proliferation of weapon prototypes.

Additionally, international cooperation is vital in addressing these regulatory challenges. Countries must work together to establish common standards and practices to prevent the global spread of unregulated 3D printed weapons. This collaboration could take the form of treaties or agreements that ensure all nations adhere to similar guidelines, ultimately fostering a safer environment.

As we move forward, it is essential to engage in ongoing discussions about the ethical responsibilities of those involved in 3D printing technology. Stakeholders—from engineers and designers to policymakers—must collaborate to create a framework that promotes innovation while safeguarding society. It's a delicate balance, but one that is necessary to ensure that the benefits of 3D printing in weapon prototyping do not come at an unacceptable cost.

- What are the main ethical concerns surrounding 3D printed weapons?

The main concerns include the potential for misuse, the moral responsibilities of manufacturers, and the impact on public safety. - How can governments regulate 3D printed weapons?

Governments can implement licensing requirements, control materials used, and require design registration to mitigate risks. - Is international cooperation necessary for regulating 3D printed weapons?

Yes, international cooperation is essential to establish common standards and practices to prevent the unregulated spread of 3D printed weapons.

Frequently Asked Questions

- What is 3D printing and how does it work?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital file. It works by laying down successive layers of material until the object is fully formed. This technology can use various materials such as plastics, metals, and even ceramics, allowing for a wide range of applications, including weapon prototyping.

- How has 3D printing changed weapon prototyping?

3D printing has revolutionized weapon prototyping by significantly reducing the time and cost associated with traditional methods. It allows for rapid design iterations, enabling engineers to test and refine weapon prototypes quickly. This agility is crucial in responding to emerging threats and adapting to new military strategies.

- What are the main benefits of using 3D printing for weapon prototypes?

The main benefits include enhanced design flexibility, reduced production times, and improved customization options. With 3D printing, designers can create complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This leads to more innovative and effective weapon designs.

- What challenges did traditional weapon prototyping face?

Traditional weapon prototyping faced several challenges, including lengthy development cycles, high costs, and limited resource availability. These obstacles often delayed the deployment of new technologies, making it difficult for military forces to keep pace with evolving threats.

- Can you provide examples of 3D printed weapons in use?

Yes! There are several case studies showcasing the successful implementation of 3D printed weapons. For instance, some military forces have utilized 3D printing to create parts for firearms and even drones, demonstrating the technology's effectiveness in real-world applications.

- What is the future of 3D printing in weapon prototyping?

The future looks promising, with advancements in materials and techniques expected to enhance the capabilities of 3D printing. Additionally, the integration of AI and automation could streamline the design and production processes, making weapon prototyping even more efficient.

- What are the ethical concerns surrounding 3D printed weapons?

There are significant ethical considerations, including the potential for unregulated production and distribution of weapons. Manufacturers and governments must navigate these concerns to ensure responsible use of 3D printing technology in the defense sector, balancing innovation with safety and regulation.